Operating range

- For single reel as well as narrow reels and multi-core-usage

- For any type of cores ≥ Ø 70 mm

- Converting applications with web-edge-adjustment

Operating range

Characteristic features

Characteristic features

|

|

|

|

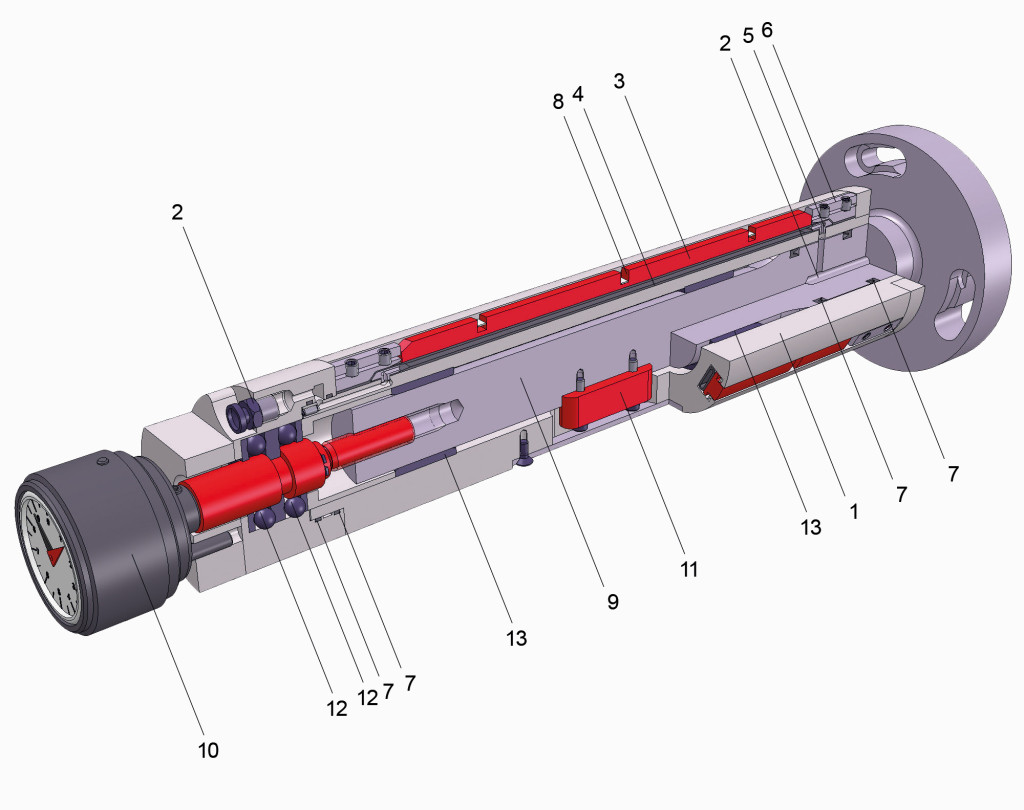

Winding cores Any kind as e.g. cardboard, plastic, metal Standard for core size Ø 75 mm / 3" and Ø 150 mm / 6" |

|

≥ 70 mm |

| Slit with of multi-reels – minimum (only for winding trunnions) |

|

≥ 10 mm |

|

Concentricity for winding depends on clearance between outer diameter of winding shaft and inner core diameter |

|

≥ 1,0 mm |

| Actuation tool Air-pistol, deflation tool |

|

|

| Optional: Spanntec CMS (Condition Monitoring System) Digital system for condition monitoring of reel tightening units which ensures maximum process reliability More information |

|

Construction

Interested in this product? Then use our enquiry form!