Operating range

- For the precise cutting of winding cores ready for use with high edge quality

Operating range

Characteristic features

Application data

|

CCM 2000 max. 2000 mm Pappe 3" / 76,2 mm 6" / 152,4 mm ≤ 210 mm ≥ 5 - ≤ 18 mm min ≤ 20 mm max. 600 mm max. 1930 mm ±0,2 mm |

CCM 3000 max. 3000 mm Pappe 3" / 76,2 mm 6" / 152,4 mm ≤ 210 mm ≥ 5 - ≤ 18 mm min ≤ 20 mm max. 600 mm max. 2930 mm ±0,2 mm |

|

Machine data

|

CCM 2000 max: 427 min-1 max: 200 mm/s Schnitte/min slits/min. 18 |

CCM 3000 max: 427 min-1 max: 200 mm/s Schnitte/min slits/min. 18 |

|

|

Measurements Length Width Height |

CCM 2000 3000 mm 400 mm 1300 mm |

CCM 3000 4000 mm 400 mm 1300 mm |

|

|

Requirement of energy System voltage Control voltage |

CCM 2000 230V AC; 50/60 Hz 10 A |

CCM 3000 230V AC; 50/60 Hz 10 A |

|

|

Pneumatik Air pressure Air consamption |

CCM 2000 6 bar 1 m3/h |

CCM 3000 6 bar 1 m3/h |

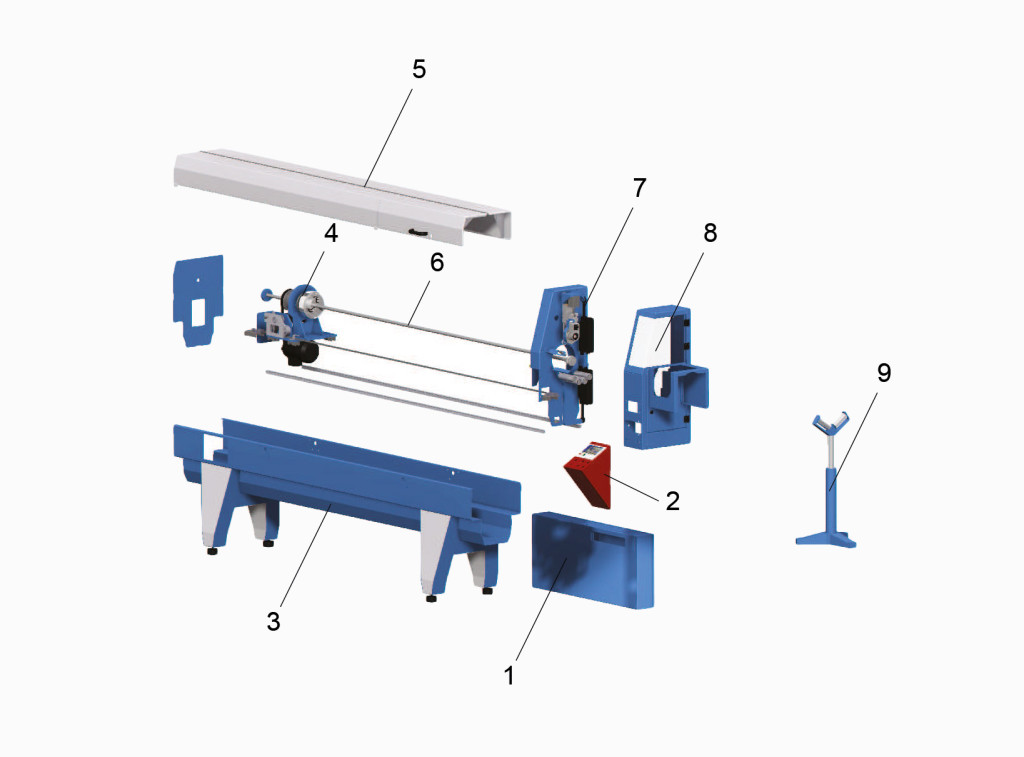

Construction