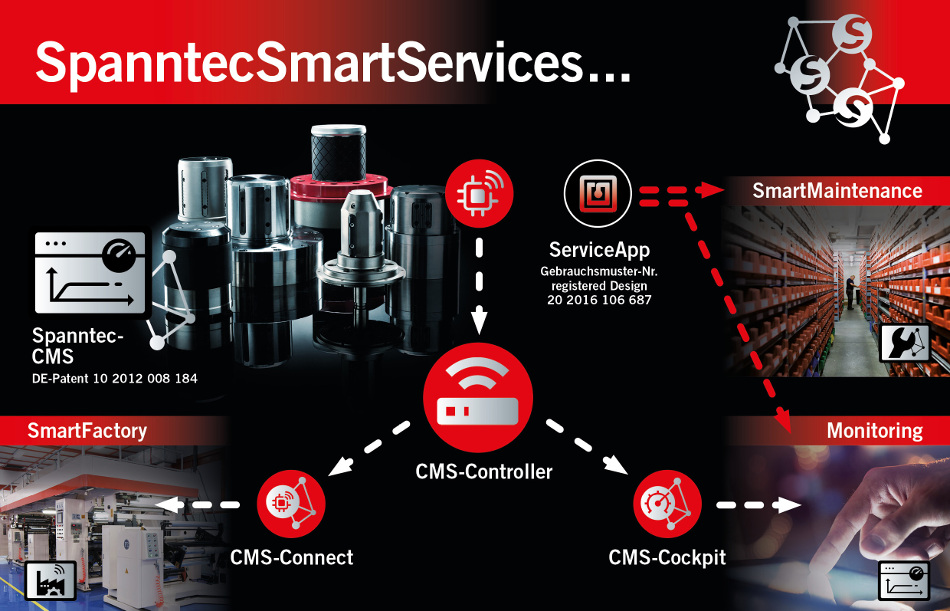

Our control system for smart reel tightening units 4.0

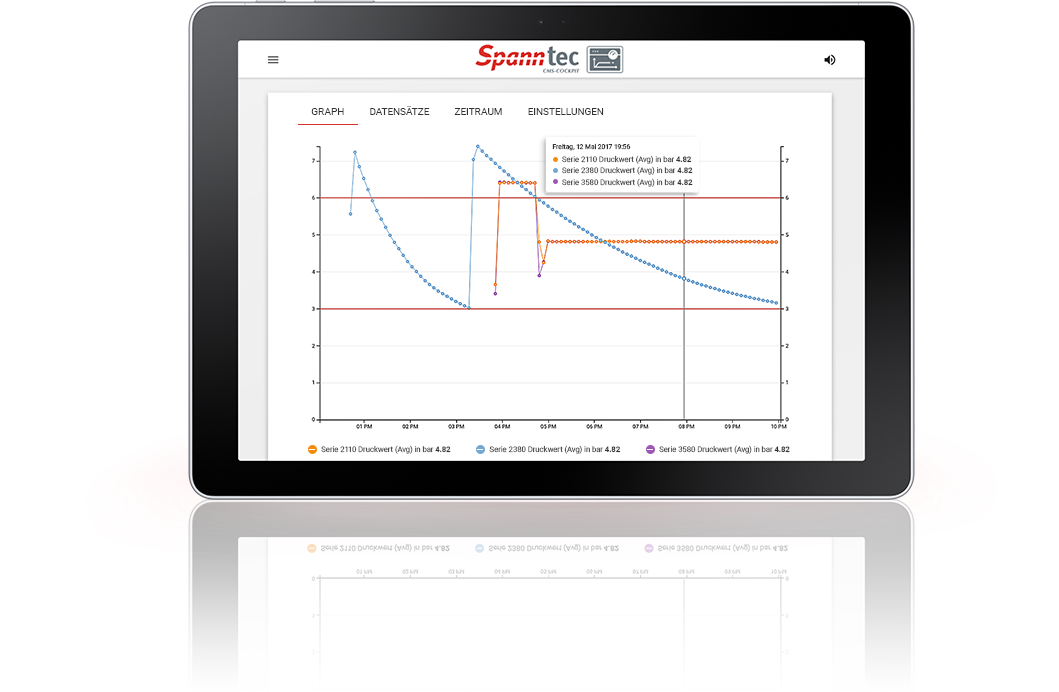

- Permanent condition monitoring

- Process data analysis

- Visual/acoustic warning system in event of disruptions

- Service and maintenance indicators

- Foreseeable maintenance

- Identification system

- Information tool

- Statistics module