Operating range

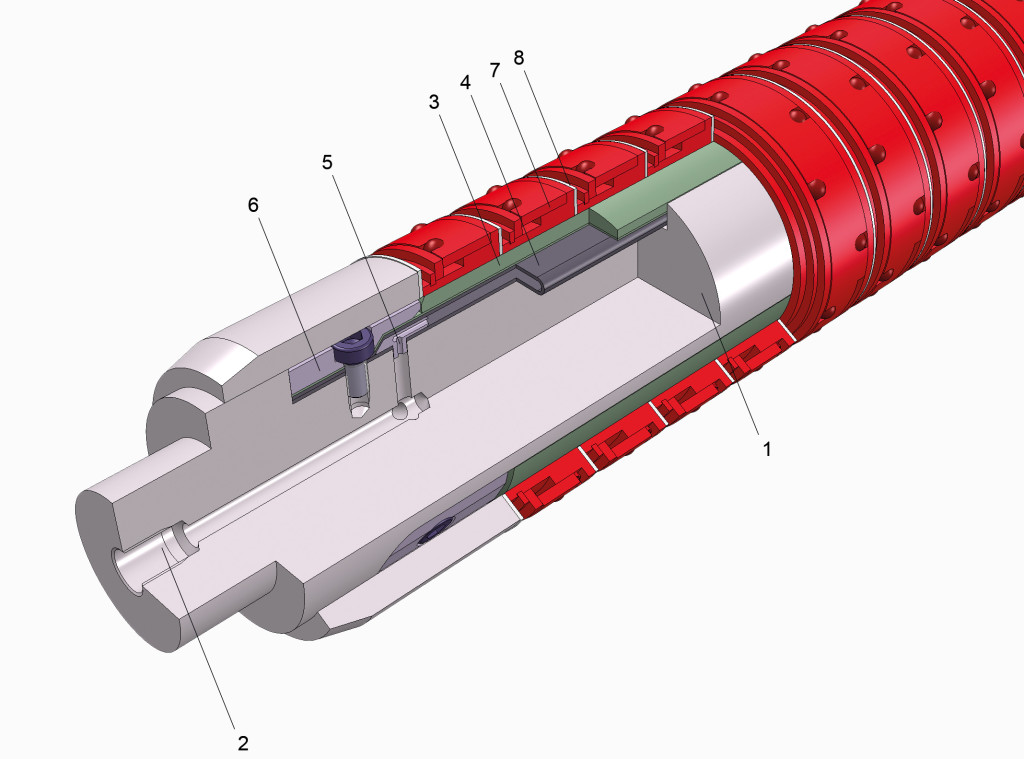

- Differential shaft for multi-reel-rewinding of materials of unequal thickness

- Used on centre-driven slitters and re-reeling machines with longitudinal section

- For cardboard and plastic cores ≥ Ø 55 mm

Operating range

Characteristic features

Characteristic features

|

|

|

| Winding cores Quality cores of cardboard or plastic |

|

≥ 55 mm |

| Slit with of multi-reels - minimuml |

|

≥ 10 mm |

| Concentricity for winding |

|

≥ 0,1 mm |

| Actuation tool Controlled permanent air supply |

Construction

Interested in this product? Then use our enquiry form!